1. Under the Trend: Why Have Double-Shaft Shredders Become a "Must-Have" for Environmental Enterprises?

With the advancement of the "dual carbon" goals and the acceleration of "zero-waste city" construction, solid waste management has long shifted from "passive cleanup" to "active resource recycling". In the past, single-shaft shredders were prone to jamming and uneven crushing when handling large-sized materials; hammer crushers, on the other hand, had high noise levels and energy consumption, making them unable to meet the demands of refined processing.

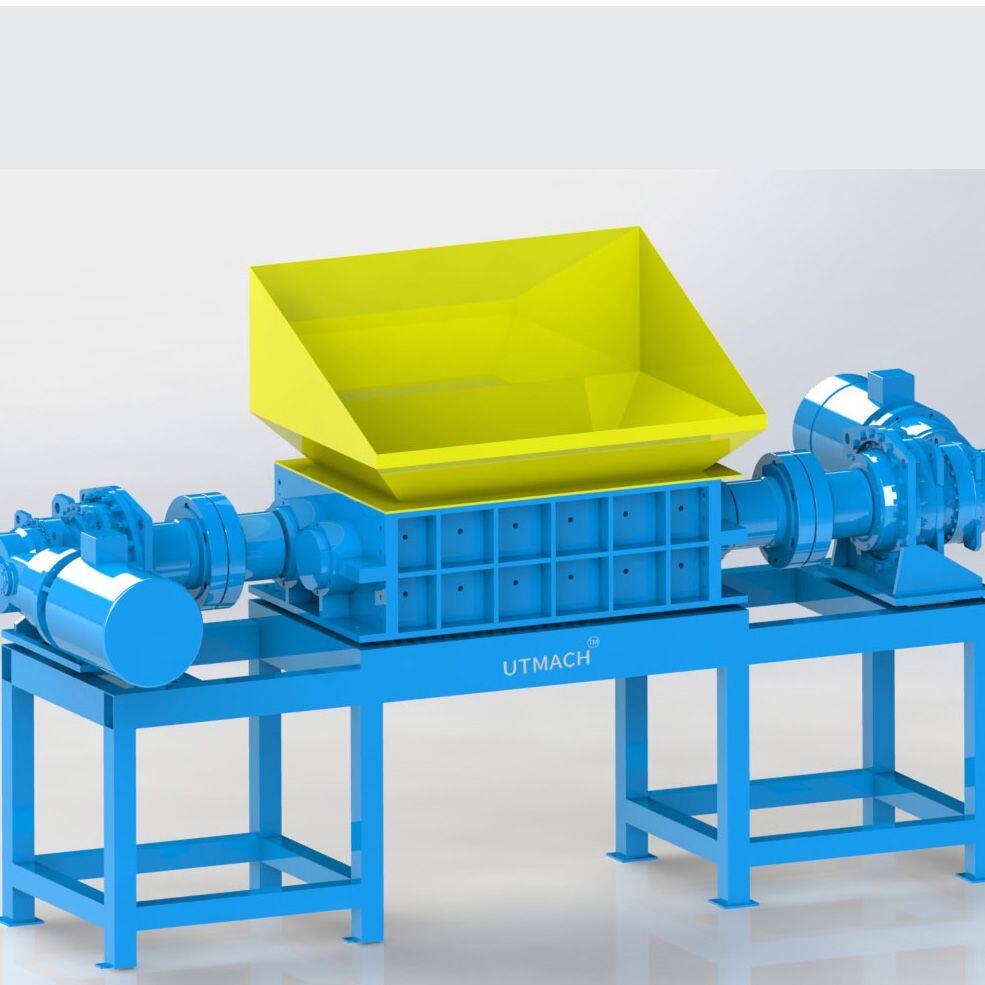

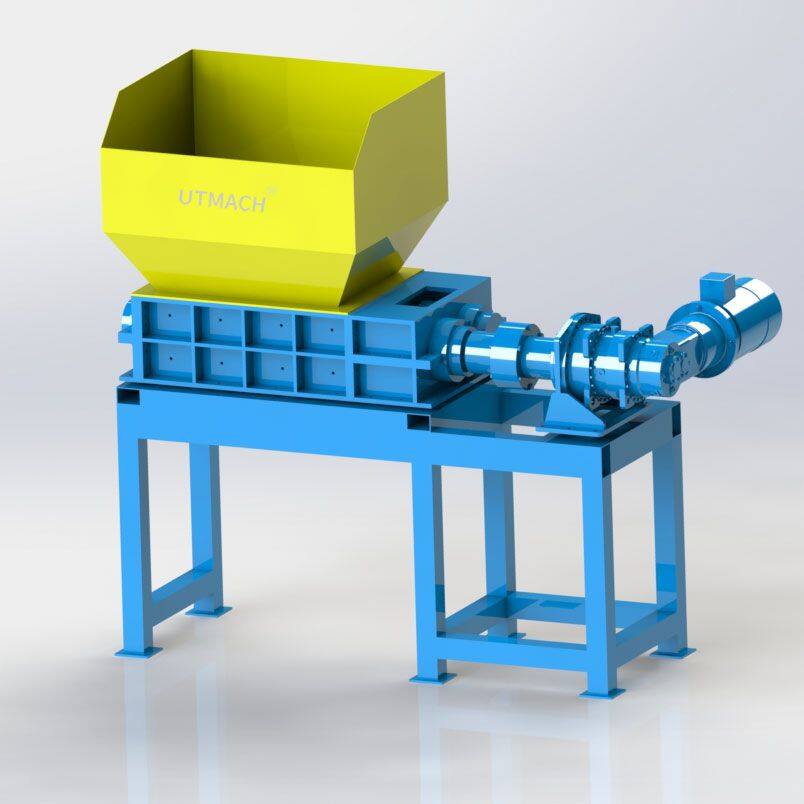

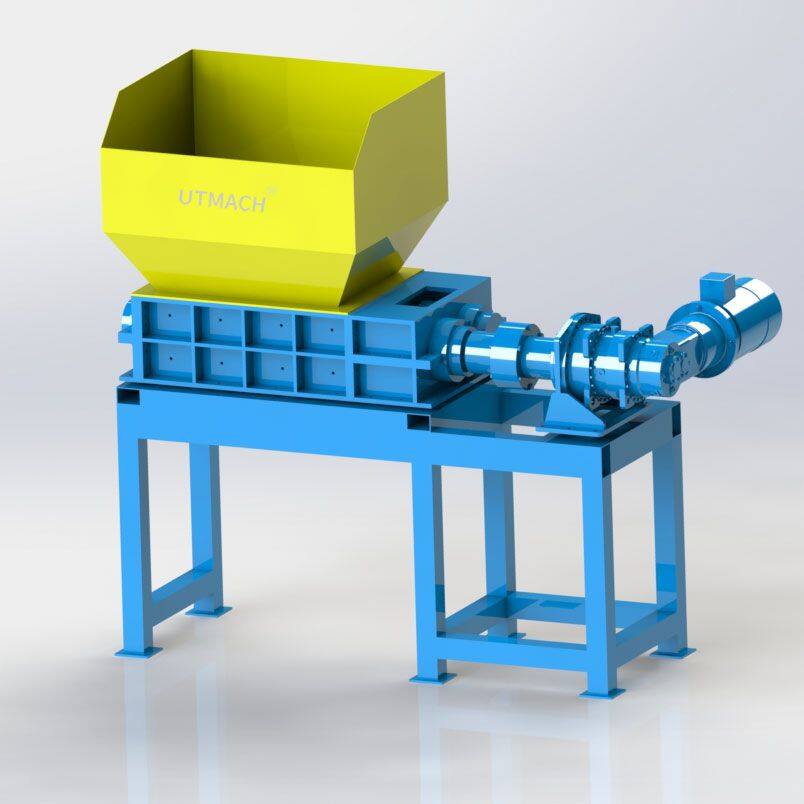

However, double-shaft shredders, with their characteristics of "low speed, high torque, and strong compatibility", can not only easily handle complex materials such as tires, plastics, and metals but also lay the foundation for subsequent resource recycling (e.g., granulation, smelting, and recycled aggregate processing) through precise control of output particle size. They have thus become a "core tool" for environmental protection enterprises to reduce costs and improve efficiency.

Nowadays, from small county-level solid waste treatment stations to large-scale renewable resource industrial parks, dual-shaft shredders can be seen everywhere. They are not just "waste-breaking tools" but also a bridge connecting "solid waste" and "resources", turning the slogan of "turning waste into treasure" into a feasible profit model.

2. Technological Upgrades: These Innovative Designs Make Double-Shaft Shredders More "User-Friendly"!

In recent years, the technological iteration of double-shaft shredders has never stopped. More and more humanized and intelligent designs have solved the pain points of traditional equipment:

Intelligent Speed Control System: Traditional equipment has a fixed speed, which tends to be "strenuous" or "wasteful" when processing materials of different hardness. The new generation of dual-shaft shredders is equipped with variable-frequency motors, which can automatically adjust the speed of the cutter shafts according to the material hardness. When processing hard metals, the speed is reduced and the torque is increased to avoid blade wear; when processing soft plastics, the speed is increased to improve efficiency, realizing "one machine for multiple materials".

Hydraulic Automatic Feeding: For large-sized and fluffy materials (such as waste sofas and cartons), the equipment is equipped with a hydraulic feeding device, which eliminates the need for manual auxiliary feeding. This not only avoids personal safety risks but also ensures that materials enter the crushing chamber continuously and evenly, increasing processing efficiency by more than 40%.

Detachable Cutter Group Design: Replacing traditional blades requires disassembling the entire cutter shaft, which is time-consuming and labor-intensive. Today's double-shaft shredders adopt modular cutter groups. When a single blade is worn, it can be disassembled and replaced individually. The maintenance time has been reduced from 8 hours in the past to 1-2 hours, significantly reducing downtime losses.

Intelligent Early Warning Function: Sensors are used to real-time monitor the cutter shaft temperature, motor current, and hydraulic system pressure. In case of abnormalities (such as jamming or overload), the equipment will automatically shut down and issue an alarm, while displaying the fault point on the control panel, reducing the difficulty of maintenance.

3. Practical Cases: 3 "Waste Breaking" Solutions for Different Industries – See and Understand How to Use Them!

Talking about technology alone is not intuitive. Let's take a look at how different industries use double-shaft shredders to solve practical problems:

A plastic recycling enterprise processes 50 tons of waste chemical plastic drums every day. In the past, using a single-shaft shredder, due to the thick walls and high toughness of the drums, jamming often occurred, requiring 3-4 shutdowns for cleaning every day. After replacing with a double-shaft shredder with a 1200mm cutter shaft, combined with hydraulic feeding and high-hardness alloy blades, it can crush 1 ton of plastic drums in 2 hours, with uniform output particle size (about 30mm) that can be directly fed into the granulator. The daily production capacity has increased to 80 tons, and labor costs have been reduced by 50%.

A construction waste treatment station needs to crush concrete blocks and bricks generated from demolition into 5-10mm recycled aggregates for the production of permeable bricks. A dual-shaft shredder combined with a vibrating screen is used: first, the dual-shaft shredder crushes large concrete blocks (up to 1.5m) into pieces smaller than 100mm, then the vibrating screen classifies them. The qualification rate of recycled aggregates reaches 98%, and the cost per ton of aggregates is 30 yuan lower than that of purchased aggregates, saving more than 2 million yuan in costs annually.

Medical waste (such as waste syringes, infusion bottles, and contaminated dressings) needs to be crushed first before high-temperature sterilization. The dual-shaft shredder adopts a fully sealed design, with no dust leakage during the crushing process, and the cutter shaft speed is only 15r/min to avoid material splashing. After crushing, the volume of medical waste is reduced by 60%, facilitating subsequent sterilization. At the same time, the equipment is equipped with an ultraviolet disinfection function to ensure operational safety.

4. Future Direction: How Will Double-Shaft Shredders "Evolve" Further?

As the demand for refined solid waste treatment becomes increasingly prominent, the development direction of dual-shaft shredders is gradually clear:

More Intelligent Linkage Systems: In the future, intelligent linkage between "shredders + sorting equipment + downstream processing equipment" will be realized. For example, AI will be used to identify material components, automatically adjust the cutter shaft gap and speed, and at the same time, real-time crushing data will be uploaded to the cloud platform to achieve remote monitoring and fault diagnosis.

More Environmentally Friendly Designs: Low-noise motors and dust collection devices will be adopted, combined with degradable lubricating oil to further reduce the equipment's impact on the environment. At the same time, more recycled steel will be used in the fuselage materials to realize "environmental protection in equipment production".

More Segmented Machine Models: For special materials in the new energy field, such as waste lithium batteries and photovoltaic panels, special double-shaft shredders will be launched, equipped with anti-corrosion cutter shafts and explosion-proof systems to meet the high safety and high refinement crushing needs.

5. Conclusion: Choosing the Right Double-Shaft Shredder is Choosing the Key to "Environmental Protection and Profit"

In the wave of solid waste resource recycling, dual-shaft shredders are no longer just simple "crushing tools" but core equipment that determines an enterprise's processing efficiency and profit margin. Whether you want to reduce solid waste treatment costs or develop renewable resource businesses, choosing a dual-shaft shredder that suits your needs can help you achieve both "environmental protection" and "profit".

If you encounter material crushing problems in practical applications or want to know the detailed parameters of a certain type of segmented machine, please feel free to communicate in the comment area. Let's explore more efficient solid waste treatment solutions together!

Tags: Shredder, Double-Shaft Shredders

Scarlett

Hi there! Welcome to my shop. Let me know if you have any questions.

Scarlett

Hi there! Welcome to my shop. Let me know if you have any questions.