-

Scarlett

Hi there! Welcome to my shop. Let me know if you have any questions.

Scarlett

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

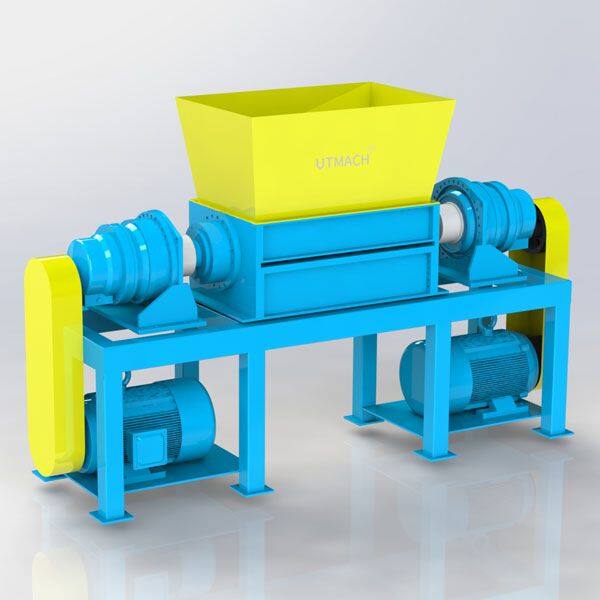

Single-Shaft Shredder: Industrial Waste’s Efficient Handler

2025-10-28 11:27:08

Resource Recycling Field: Crushing waste plastic bottles, plastic sheeting, and woven bags. The recycled fragments can be directly used for the production of recycled pellets; processing waste paper such as waste cartons and newspapers to realize pulp recycling and reuse.

Industrial Production Field: Crushing leftover materials and unqualified products in the injection molding industry for direct remelting and recycling; pulverizing wood scraps and branches to make biomass fuel or raw materials for artificial boards.

Environmental Protection Treatment Field: Decomposing medical waste and kitchen waste to reduce landfill space; crushing waste home appliance casings and auto parts to separate metal and non-metallic materials, improving resource recovery rate.

Special Scenario Applications: In places with limited space such as small waste treatment stations and laboratories, the compact design of single-shaft shredders can better highlight its advantages and easily integrate into the existing production lines.

Cutter Shaft Speed and Power: When processing light and thin materials (such as plastic films), it is recommended to choose models with high speed (15-30r/min) and low power (5.5-15kW) for higher crushing efficiency; when processing hard materials (such as metals and wood), it is necessary to choose models with low speed (5-15r/min) and high power (15-45kW) to avoid cutter shaft jamming.

Discharge Particle Size Adjustment: High-quality single-shaft shredders can realize discharge particle size adjustment of 0.5-50mm by adjusting the cutter head gap. If subsequent fine processing is required, it is recommended to choose a model with a large adjustable range of gaps.

Machine Body Material and Protection: The machine body should be welded with thickened steel plates to ensure impact resistance; the cutter head should be made of Cr12MoV alloy material for wear resistance and durability; at the same time, it should be equipped with dust-proof and noise-reduction devices to meet environmental protection requirements.

Regularly check the wear condition of the cutter head. When the blade wear exceeds 2mm, grind or replace it in time to avoid cutter shaft deformation caused by uneven force.

Before starting the machine each time, check the lubricating oil level to ensure that the cutter shaft bearing is fully lubricated. It is recommended to replace the lubricating oil every 500 hours of operation.

Avoid mixing in unbreakable hard objects such as stones and steel bars. When feeding materials, it should be uniform and continuous to prevent equipment overload.

Tags: Shredder